Laupahoehoe Sugar Company was located at Laupahoehoe on the Hamakua Coast of the island of Hawaii. The coastline, from Hilo Bay to Niulii, is bordered by sea cliffs and cut by steep gulches. The plantation fields extended approximately 10 miles along the coast and rose to 1850 feet above sea level. Ending in high sea cliffs, 22 gulches divided the company land.

In 1880, Theophilus H. Davies and William Lidgate formed a partnership and established the Laupahoehoe Sugar Company. The new plantation employed 70 men, 50 mules and 70 oxen. Mr. J.M. Lydgate became Laupahoehoe’s first manager and Theo. H. Davies & Co. served as its agency. At the time of this writing, the relationship between William Lidgate and J.M. Lydgate is not clear.

Honolulu Iron Works was chosen to manufacture a 15-ton mill, which was erected in 1881 at the shoreline site near a high bluff two miles south of Laupahoehoe. Cane was flumed down the bluff to the mill from fields as far as four miles away. An excellent landing for interisland ships was one of the advantages of the site.

In 1882, a severe storm badly damaged the new mill, causing part of the bluff to fall into the factory. The mill was repaired and sugar continued to be manufactured there until 1890.

In 1882, a severe storm badly damaged the new mill, causing part of the bluff to fall into the factory. The mill was repaired and sugar continued to be manufactured there until 1890.

The Laupahoehoe Sugar Company was incorporated in 1883 and in the following year the Kaiwilahilahi Sugar Company joined with Laupahoehoe. The records indicate that at least two mills were operating at Laupahoehoe Sugar Company during the 1880s, one of which was the Kaiwilahilahi mill and the other was the Laupahoehoe mill. Mr. Lydgate had a third mill built for the Company, this one at Papaaloa. The records are not clear as to exactly when this mill was erected, though the mid-1880s seem likely. Both the Laupahoehoe mill and the Kaiwilahilahi mill closed in 1890 and all Laupahoehoe Sugar Company cane was ground at the Papaaloa mill.

Laupahoehoe Sugar boasted a unique transportation system to supply the factory with cane. A steam hoist lifted cane-loaded cars up 1100 feet by cable at Maulu Gulch. At the top, the cane was dumped into flumes and traveled to the mill about a mile distant. In 1909, an area of 360 acres was set aside for homesteads and in 1914 another 950 acres were so designated under the Homestead Act. The homesteaders grew cane under contract which they sol to Laupahoehoe Sugar. The Company purchased cane from adherent planters holding various kinds of contracts. Some planters were independent, some were homesteaders and some were members of contract gangs.

By 1920, about half the original cane land was planted and harvested by homesteaders and the other half was cultivated by Laupahoehoe Sugar Company. In 1918, the annual yield was 12000 tons of sugar.

The plantation was noted for having model plantation camps. The camp houses were surrounded by garden space, and playgrounds and concrete bathhouses were provided. In 1918, 12 plantation camps housed the 900 laborers employed by Laupahoehoe Sugar.

Because of the extensive gulches in the plantation fields, flumes were used instead of railways to transport the harvested cane to the mill. In 1922, a new high life pump was installed to move two million gallons of water a day out of Kaawalii Gulch up to the head of the main flume at the 750-foot level. The main flume carried 30 tons of cane per hour to the mill. Laupahoehoe Sugar was the first plantation in Hawaii to lift water for fluming as high as 750 feet.

Because of the extensive gulches in the plantation fields, flumes were used instead of railways to transport the harvested cane to the mill. In 1922, a new high life pump was installed to move two million gallons of water a day out of Kaawalii Gulch up to the head of the main flume at the 750-foot level. The main flume carried 30 tons of cane per hour to the mill. Laupahoehoe Sugar was the first plantation in Hawaii to lift water for fluming as high as 750 feet.

Contour plowing and planting were used to prevent erosion on the uneven terrain and, while he was manager, Mr. Lydgate introduced the practice of planting his fallow fields to blue lupine for erosion control and to plow under as green manure.

In 1937, there were about 6400 acres of cane land at Laupahoehoe Sugar Company, some being cultivated by homesteaders and planters and some by the Company. A total of 881 people worked at Laupahoehoe, 60% of who came from the Philippines. American citizens comprised 25% of the Company employees and 75% were citizens of other countries.

A plantation hospital was completed in 1937, giving plantation workers the latest in medical care. Continuing to improve living condition on the plantation, large expenditures were also made in 1938. Water was piped to every dwelling, villages were modernized, clubhouses, parks, the gymnasium and community halls were remodeled or built for the benefit of the laborers. In 1941, the plantation office was air-conditioned and new homes of the bungalow type were built.

In 1943, the historic Maulu Gulch hoist was destroyed when the brake on a loaded can car snapped and the car crashed down the 1100-foot incline.

Laupahoehoe Sugar Company aided the war effort and the U.S. armed forces by providing men for guard duty and to drive trucks. Housing and recreational facilities were leased to the Army for the duration of the war.

The managers of Laupahoehoe Sugar Company during the time covered by this brief history include:

J. M. Lydgate, 1880-1888,

Colin McLennan, 1889-1914,

Robert A. Hutchison, 1915-1944

Andrew Walker, 1944-

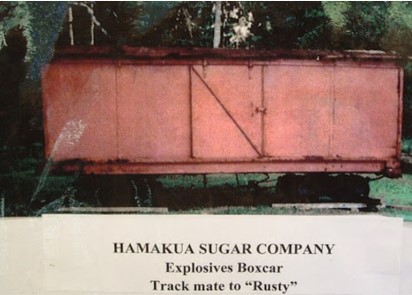

During October of 1987, all Hamakua Sugar Company records, or, approximately 445 cubic feet of material were removed from storage, fumigated and brought into the Archives. The Laupahoehoe Sugar Company (LSC) records, a total of 48 boxes and 103 items, or approximately 87 cu. ft., were segregated from other records of the Hamakua Sugar Company during November 1987. By March 1988, all LSC records were processed and ready for use.

Sources

Deborah A. Saito

Susan M. Campbell

www2.hawaii.edu/